What is a cable?

The steel ropes are a simple solution for multiple mechanical applications.

Composition of a cable

The advantageous properties of strands and wire ropes are recognised at the product design stage. Strands are made up of wires that are joined together by means of stranding. They are the basis for all rope constructions and micro steel cable manufacturing. 7, 19 or 37 strands can be combined; the higher the number of wires in the strand, the more flexible it is and the longer the service life under repeated bending.

The strands

The strands are made of high-strength wire, wound on itself.

Cables

The ropes are obtained by committing, the construction is done by assembling several strands.

Designation of strands and ropes

A rope is denoted by: (The number of strands) x (the number of wires making up the strand).

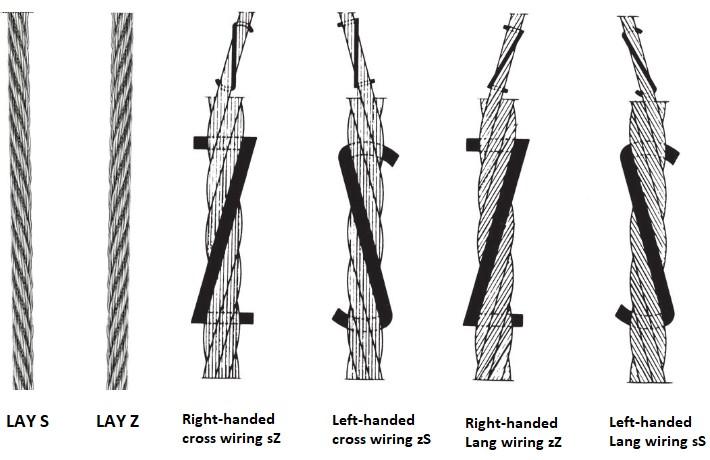

Construction of a cable

The pitch is the direction of rotation of the wires around the central core (textile or metal). If the outer wires (or strands) are laid to the left around the core, the rope is said to be left-hand lay “S”. If the wires (or strands) are laid to the right, the rope is referred to as right-hand lay (or not) “Z”. For ropes, a distinction is also made between cross-lay and Lang lay. In the absence of a specification, the direction of twist will usually be right-hand lay.

Standard constructions

The strands

0.09 – 0.75 mm

- Tensioning or holding elements

- Suspension cables

0.15 – 5.00 mm

- Tensioning or holding elements

- Control cable

- Reinforcements for belts

Cables

Textile core

6×7 AT : 1.5 – 5.00 mm

Metal core

7×7 : 0.12 – 6.00 mm

- Guide cables for printers, copiers …

- Tension or holding cables

- Ideal for low to moderate cycles

Textile core

6×19 AT : 3.00 – 8.00 mm

Metal core

7×19 : 0.45 – 8.00 mm

- Control cables with more intensive cycles

- Shade cable

Textile core

6×37 AT : 6.00 – 8.00 mm

Metal core

8×19 + 7×7 : 0.57 – 4.00 mm

- High cycles and frequencies e.g. in textile machines or precision printers…

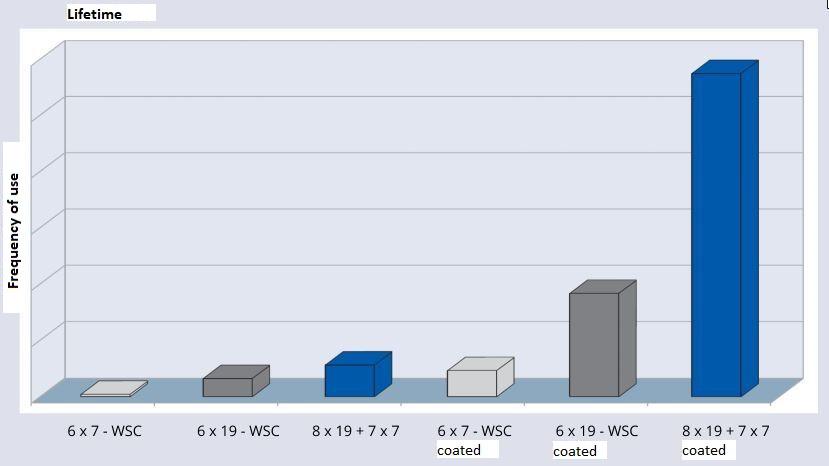

Lifetime

Our experience is at your service and we recommend the product best suited to your use. However, we can only determine its service life by means of physical endurance tests. Therefore, we offer you tests based on your specifications, as the behaviour of the cable or the sheath is linked to multiple factors, for example :

- Permanent stresses

- Dynamic constraints

- Speed

- Acceleration

- Oblique traction

- Course

- Tensile tests

- Alternating bends

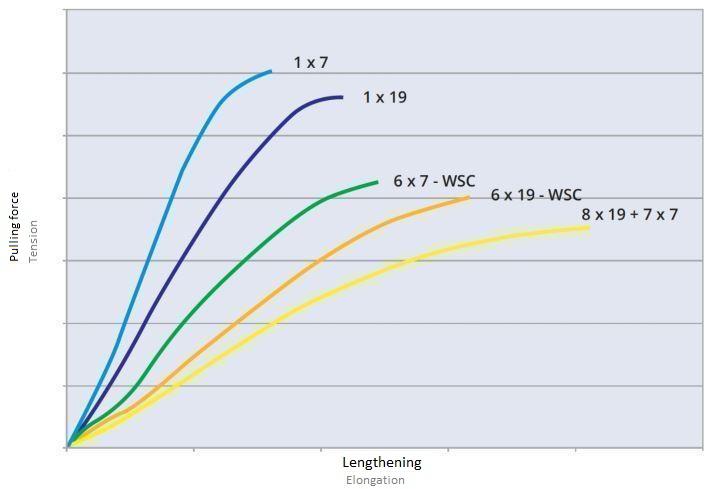

Lengthening

We distinguish between two types of rope elongation: one due to the construction, the other due to the material.

Rope elongation due to construction :

Small residual voids remain between the wires or strands at the time of manufacture. Under tension, the composition tightens and densifies, producing elongation. This elongation is not the same for all ropes and depends on their construction and the direction of twist.

Material-related rope stretch :

This occurs when the rope or strand is stressed to its point of deformation. Elongation is generally proportional to the force applied. After the load is removed, the ropes are almost back to their original length, as the elastic limit has not been reached and therefore no permanent deformation remains.