Flexible shafts

Codica flexible shafts are a superposition of layers of steel wires on top of each other. The layers of threads intersect at different angles. The mechanical properties are determined by the quality, quantity and diameter of the wires. The assembly method is decisive to ensure flexibility, torsional forces, speed in one or two directions of rotation.

High speed flexible shafts couplings

The flexible shafts type H - High Speed are intended for intensive use in systems with limited noise and vibration. High speed flexible shafts reach speeds up to 3500 rpm

Power transmission flexible shafts

Codica's SL8 flexible shafts are designed for bi-directional use, i.e. clockwise and anti-clockwise. These flexible shafts accept smaller bending radii. The SL8 type flexible shafts are designed for speeds up to 10,000 rpm with constrained torque transmission.

Adjusting shafts

Adjusting shafts type SL16 are designed for use in both clockwise and counter-clockwise rotation. With this type of shafts, high torques can be transmitted at speeds up to 150 rpm. This type of shaft is particularly suitable for use with hand tools, screwdrivers, etc.

End caps for flexible shafts

Flexible shaft ends are machined parts that are crimped onto flexible shafts. There are certain standards but other solutions are possible.

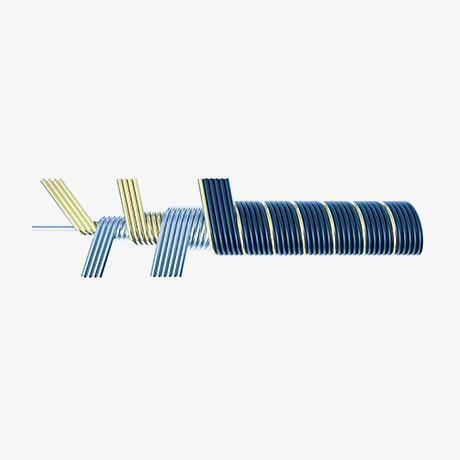

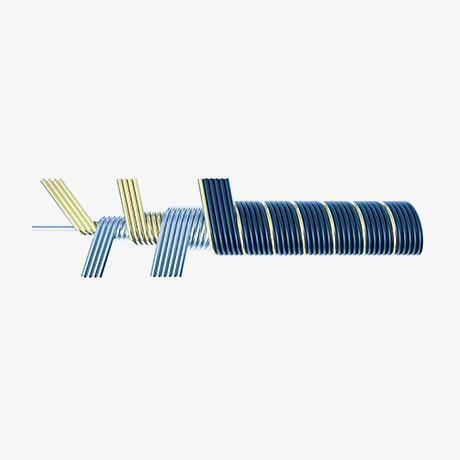

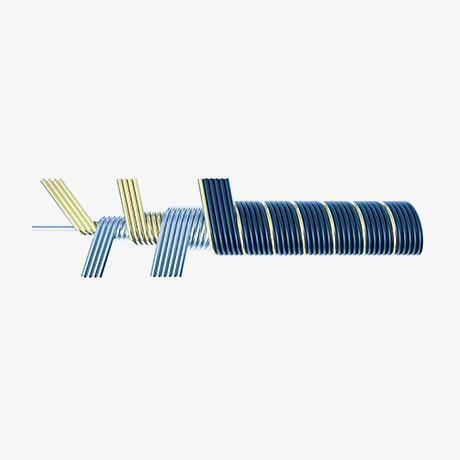

Helix cables shafts

Helix cables shafts are flexible shafts with a wire around the circumference of a specific diameter. The function of these shafts is to transmit a force in PUSH PULL. Accompanied by a guide tube, these shafts are used in the sunroofs of passenger cars or in the blackout of the roof.

Rack cables

Rack and pinion ropes have a PUSH PULL function, which is a traction rope wound with a wire at a certain pitch.