Codica metal sheaths

What types of sheathing are used for what purpose?

The requirements of a system are often complex. Every detail counts. A sheath is a wire or wire assembly wound on itself.

The width, thickness, material and strength class of the wire will affect the behaviour of the metal sheath.

Flat wire or round wire sheathing, also known as Bowden sheathing, for the engineer who invented it, is an industry standard, a technology that has been used for decades.

Codica transmission cables has over 60 years of experience in its manufacture and processing. Each type of sheath has its advantages depending on the application.

Different type of colours and specific material are available according to a minimum of quantity.

Please contact one our expert to share your request.

Black PVC coated flat wire sheath

The most common type of wire mesh tubing used in industry is the flat wire jointed wire tubing, also known as Bowden tubing. Codica flat wire tubing is flexible and robust, ideal for repeated use applications.

Bending radius :

To define the minimum bend radius of a conduit, conduit diameter X 25 = minimum installation diameter.

The jacket is usually plastic and can meet anti-flammability or high temperature requirements.

Flat wire metal sheath with black PVC coated inner tube

Codica’s flat wire conduit is flexible and robust, ideal for heavy-duty applications thanks to the POM inner tube. The contact point between turns is wide, which gives good rigidity and low compression.

Bending radius :

To define the minimum bending radius of a liner, liner diameter X 25 = minimum installation diameter.

The lining of the duct is usually plastic and can meet anti-flammability or high temperature requirements.

Black PVC coated round wire sheath

The round wire sheath without inner tube.

Codica round wire tubing is flexible and robust, ideal for repeated use applications.

The point of contact between turns is punctual which gives perfect flexibility but limits resistance to compression.

Bending radius :

To define the minimum bending radius of a flat wire jacket. Duct diameter X 20 = minimum installation diameter.

The Codica liner is usually plastic and can meet anti-flammability or high temperature requirements.

PUSH PULL sheath with black PVC coated inner tube

PUSH PULL with inner tube is an assembly of wire stranded lengthwise on a POM tube or other material.

Codica PUSH PULL has better compressive stability for repeated use than a metal spiral hose.

PUSH PULL offers less flexibility but is lighter than round or flat wire spiral versions.

Bending radius :

To define the minimum bending radius of a PUSH PULL duct. Duct diameter X 40 = minimum installation diameter.

The Codica liner is usually made of plastic and can meet anti-flammability or high temperature requirements.

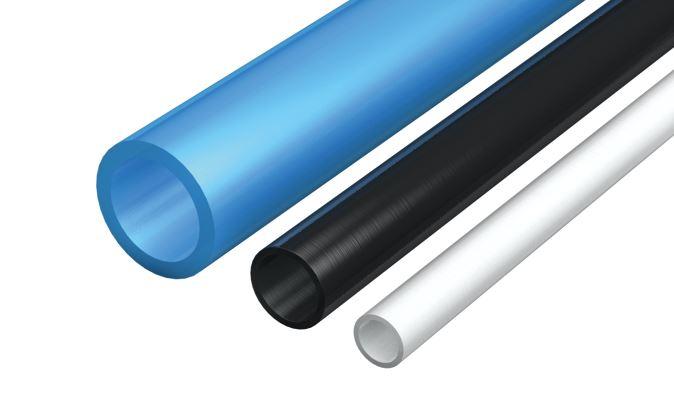

Plastic tube or sleeve

Plastic pipes or sleeves are extruded pipes made of POM, PE.

In cases where the forces are low or the guidance is provided by another metal element such as a rail, the pipe is used as a guide element.

The tube is light and can withstand light loads with repeated use.

Bending radius :

To define the minimum bending radius of a PUSH PULL duct. Diameter of the duct X 100 = minimum installation diameter.

The Codica liner is usually made of plastic and can meet anti-flammability or high temperature requirements.

When using a steel wire rope and metal sheath pair. The wire rope translates in the sheath between the start and end position. Between these two positions we have an effect called “Lost Motion” see diagram on the right.