Crimped wire rope ends & ferrules

"The right cable end for every project".

A crimped cable end is a machined piece of treated steel that is cold formed onto the cable using dedicated tooling and a pneumatic, hydraulic or mechanical press. With over 60 years experience in this type of process, Codica has a wide range of tested and approved components.

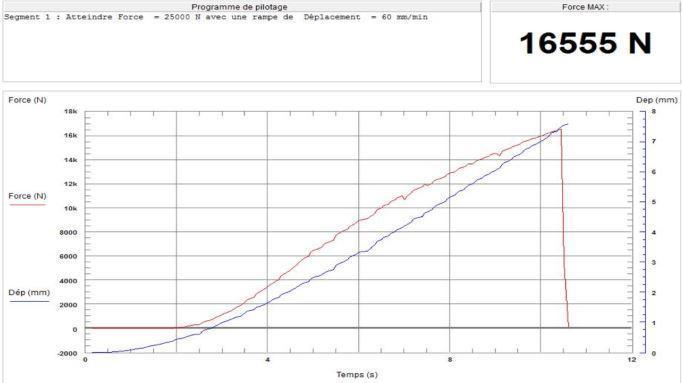

We test cable terminations by destructive testing on specimens at the beginning of the manufacturing order. The dimensional and mechanical performance criteria communicated for the wire rope assembly are important to ensure that the manufacturing process is monitored.

Each wire rope end fitting has its own advantages. Spherical rope ends have freedom of rotation, eyelet have ease of attachment to a frame, threaded rods have quick adjustment of rope tension, and many other solutions exist. Ask our technicians for more advice.

Zamak injected steel cable ends & zamak injected cable ferrules

A zamak cable end is an overmoulding on the galvanised or stainless steel cable by means of an injection mould. The mechanical properties are close to or identical to the mechanical cable, depending on the size. The constraints are the volume of parts per manufacturing batch. The minimum production volume is 1000 pieces to pay for the installation of the injection tooling.

We test the cable terminations by destructive testing on specimens at the beginning of the manufacturing order. The dimensional and mechanical performance criteria communicated for the steel cable assembly are important to monitor during manufacture.

Codica has a wide range of standard tooling.

Which cable ends to achieve good mechanical strength between cable and ends?

The use of the rope/end assembly is decisive as well as the main function of the assembled rope, e.g. a brake rope or a luminaire suspension has a direct or indirect safety function.

Many factors come into play, such as the construction of the cable, the type of material, the shape of the cable end.

Together with you, we determine the minimum force to be achieved, define a safety coefficient and test the products supplied during manufacture.

The mechanical strength in Newtons of the crimped or injected cable is our guideline.

CODICA is certified according to the ISO 9001 standard, in order to guarantee a product that meets your requirements and the applicable regulatory requirements, in an environment of continuous improvement.

Our catalog

Download our free aeronautical cable catalogue by entering your email address.